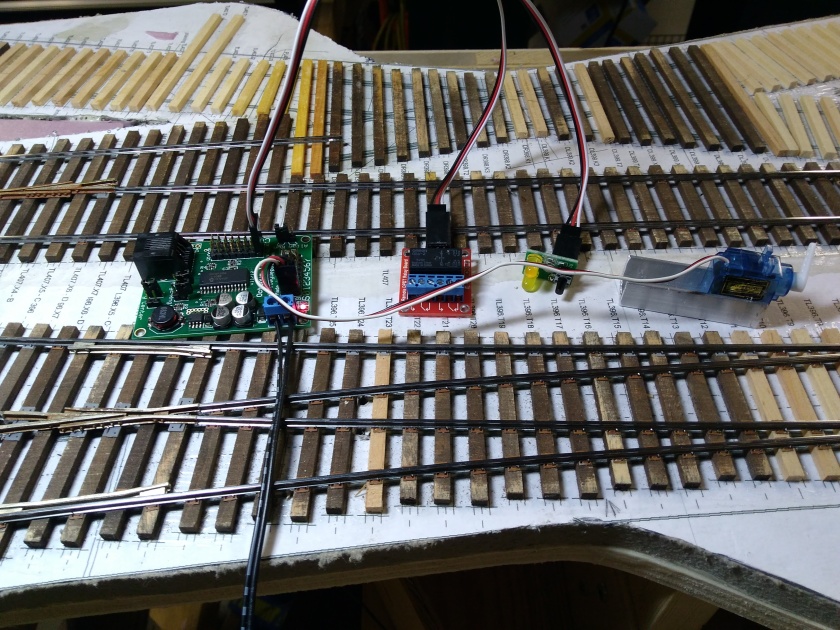

Pictured above are in order, an Octopus III servo controller, remote relay, fascia controller and micro-servo, all from Tam Valley Depot. I bought a bunch of each for the previous layout and never did get any of it deployed so I am both pleased to be finally using it all and having to learn how to do that.

Tonight I soldered up a fascia controller kit (two LED’s, a button and a connector) and messed around with the remote alignment board to get the hang of it. I think I can do it all now including, ahem, factory reset the Octopus in case I mess it up. Hypothetically speaking. 🙂

Next concern is that the required throw for the points is about 100 degrees of rotation. To get that out of the servo will require it to be quite close to the point of rotation which creates other alignment issues. I am having a bit of a ponder about what to do about that. I will also tip the board up for the next bit of fiddling since I can’t get under the bracket location with a screwdriver due to the sub-baseboard. Hopefully the assorted point bits won’t fall off since I haven’t permanently attached any of it.

Maybe I don’t understand the problem, but could you just put a longer arm on the servo so you don’t have to throw through as wide an angle?

LikeLike

Good question! I considered a longer throw arm but then the vertical shaft would have to stick out even farther. I was already concerned about how vulnerable to getting bent the linkage is. I think I am ready for plan B: mount the servo with the drive shaft facing up and in line with the vertical shaft. I found a good illustrated description of this sort of linkage on the Delmarva Model Railroad Club site: http://delmarvamodelrailroadclub.org/NeatStuff/ServoMounting/ServoLink.html

LikeLike

Nice. I am somewhat alarmed by the use of CA to mount it though! The servo will apply a sheer force to the CA joint, which is exactly the type of stress CA doesn’t like. Maybe back that up with a screw after the CA has set.

LikeLiked by 1 person

I agree, I don’t see me using CA for a wood/wood joint. I also have only four or five servos to mount unlike a large club doing a retrofit. 🙂 I am considering screw through servo mounting hole all the way to the plywood with some sort of spacer. Which may be a block of wood if I can’t find some suitably sized tube.

LikeLike