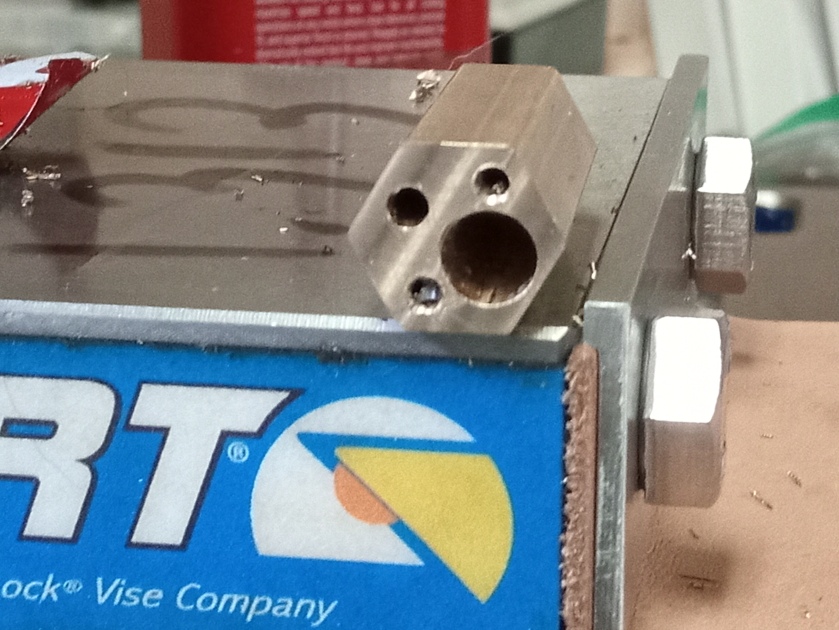

I was tapping the second of the two holes for the screws that hold the beam engine’s cylinder head onto the cylinder and carefully feeling for the bottom of the hole and…

That shiny silver bit in the bottom left small hole is what’s left of my M2.5 tap. It had to happen on the last thing, of course. I was turning the tap wrench with just two fingers on the barrel and apparently I can’t tell when it hits the bottom.

As a personal triumph of character development, I uttered only a single profanity, cleaned things up and went off to see what my options were. Unfortunately, tap extractors exist but not for taps this small. I had no luck sticking some straight pins down the flutes and twisting with pliers as an impromptu extractor. I do have some nicely spiral pins now, though. Further research brought me to the chemical approach. I am now attempting to corrode out the tap with an alum(potassium aluminum phosphate) saturated solution. And taking a day off to look at other projects/pieces of the beam engine.

Hi Mark,

Bummer of a problem. Can you put the tiniest possible amount of CA onto the end of a short piece of rod, glue it to the broken tap, and then be able to screw it out?

LikeLike

I did consider that as well as trying to solder (hard or soft) something to the end but there isn’t a lot of surface area and the tap is stuck hard enough to hold while steel pins bend into spirals. I figured that the chances of my mucking up the part in the process were much higher than the chances of any of those working out.

I have other parts to work on and sufficient material to remake the part if I must so I thought I would try this approach and see if it works.

LikeLike

That blows chunks. Sorry to hear about the set-back.

Did the chemical approach work? If not, how much trouble is it to remake the part – and did you learn anything from making it the first time around that will make the second time around better/easier?

LikeLike

Chemical approach still in progress. I expect a couple of days since I don’t have the means to boil the solution in a non-metal vessel. Boiled approach is reported to be a couple of hours.

I was quite happy with the part up to that point so I would not expect the second attempt to come out better. Having previously worked out various methods of work on the first go, the second would certainly go faster if only for not having so many pauses to ponder. Still have to go buy a new tap, though. 😛

LikeLike